The following factors must be included in any plan for producing quality frozen foods:

1. High intrinsic quality of raw materials used in the product

2. Correct processing and packaging of the product

3. Rotation of inventory throughout the “Cold Chain,” utilizing FIFO (“First In – First Out”)

4. Maintenance of uniform, sufficiently cold temperatures

Source : Frozen Food Handling and Merchandising Alliance

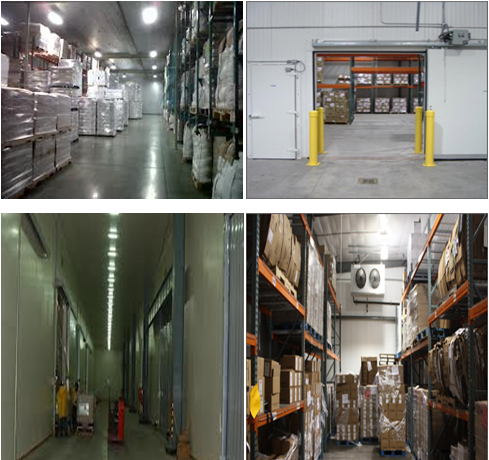

Chronos eStockcard Inventory Software has been successfully being implemented in this industry and it has greatly improved the warehouse productivity by reducing errors and achieve better control in product quality.

The Company

Involve in local & global procurement, processing and distribution of Live, Fresh and Frozen Seafood.

The Challenge

1. Numerous errors derived from paper-based processes

2. Poor expiry management

3. Slow order processing

The Solution

To implement Chronos eStockcard Inventory Software

a. IN the product

IN Screen is being used to capture essential information such as lot number, batch number, expiry date, PO number, DO number received from the supplier via very simple screen.

Storage location will be searched and suggested by the system for effective put-away.

Screen can be customized to suit your business processes.

b. OUT the product

Very simple OUT Screen or Picking List are being used for frozen goods retrieval. Inventory rotation is customizable either FIFO or LIFO.

c. Expiry Management

Alert system is embedded in the eStockcard and you can configure it to monitor the products that is-about-to-expire or already expired via email. This will greatly improve product’s expiry management processes.

The Benefits

a. Timely, Quality and Accurate data

b. Waste reduce tremendously through better expiry management and control

c. Better productivity

d. Faster order processing