All organizations with inventory are finding themselves working in confines space and money constraints. Thus finding the correct racking would increase space utilization, easy accessibility to the inventory locations, handling time and able to pick order within minutes. Inventory is also prevent from damage when it is moved from the respective spaces.

The most common racking available include: push back rack, selective, drive in racking, pallet flow rack and cantilever.

Push back rack

Each level in a Push Back Racking system holds a series of nested rolling carts which operate in a lane that slopes upwards away from the pick face. This rack acquired its name because the lift truck operator lines up in front of the first pallet and pushes against it, causing the first pallet to roll away from the pick face and expose the next cart. All carts are interlocked to prevent jamming and product damage.

Push Back Racking allows you to store multiple SKUs on different lane levels, enabling easy access. Combined with proper warehouse management, you can maintain First In First Out (FIFO) by emptying the oldest lanes first.

Selective

Selective pallets made up of vertical frames and beams that are arranged in single or double rows. It allows storing of different sizes and shapes of packaged materials and also easy, direct access to every stored load. The height between shelves can be adjusted based on the size of the loads and wire decking can be added to accommodate non-racking pallets. Labor costs are thus reduced as movement of pallets can be eliminated. Inventory control is also improved because it easier to view what is available.

Drive in racking

Drive in racking offers a high density of pallet storage with low selectivity. Consequently, it is ideal for product with a high number of pallets per SKU. When stock rotation is an issue, Drive In rack ensures that tunnels are fully emptied before replenishing. It is a LIFO – Last In, First Out high density storage system.

Drive in racking systems efficiently able to store large quantities of loads by allowing the forklift driver to enter the rack system and place the load on structural rails. The lift truck can enter the rack from one side to pick up or pull out pallets because the pallets can slide backwards on a continuous rail. While forklifts can drive into the rack to access pallets 2 or more deep, the size of your facility may limit the depth of storage for a bay.

Pallet Flow Rack

In pallet flow racking, product flows back to a picking position and is easily accessible to the operator. The product is loaded from the back and picked up from the front. This system provides high density storage because every aisle can contain product with the same SKU. Pallet Flow racking is perfect for fast-moving product with first in/first out (FIFO) rotation. Plus, warehouse floor space can be maximized with fewer aisles by storing pallets back to back.

The main parts of this storage system are static racks and dynamic roll tracks. The dyamic roll tracks are decline along the rack and used gravity to move pallets from one location to another. Each lane has brakes to control the movement of the pallets.

Pallet Flow rack suits FIFO inventory systems as loads are moved from the loading to the unloading ends whereby the first load is removed first. It is also ideal when pallets must be moved from one area to another without fork lift trucks and thus more flexibility, lower maintenance costs and less damage to racks.

Cantilever

Cantilever racks are faster to load and unload as they do not have any front columns. Thus they are useful for storing long or bulky loads. Loads may be placed anywhere along the entire length of a row and handling clearance is more abundant.

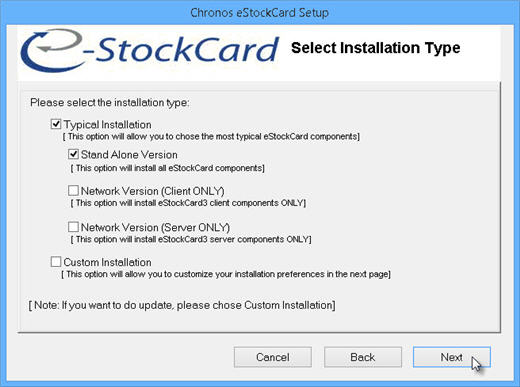

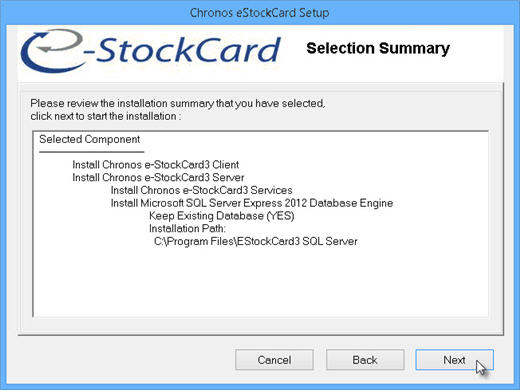

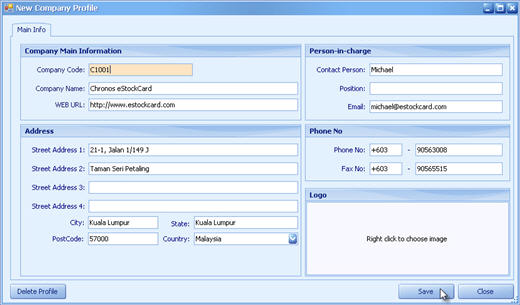

Check out Chronos eStockCard Inventory Software and see how our software can help to improve your warehouse operation.